Plasticine as a computer interface

The use of Plasticine (and equivalents) has enjoyed an ironic resurgence with the advance of affordable computer modelling technology.

While one might have expected 3D computer systems to make old-fashioned sculpting obsolete, in fact they have removed one of the main limitations of physical modelling – the fact that other than using photography or a casting (or pantographic duplication), the model tended to be a dead end with respect to what you did with it next. It used to be that one could create a physical clay model of a shape, get it right, and then laboriously recreate it in the computer by eye, or by taking measurements with calipers. Nowadays with turntable laser scanners, the sculptor can create a rough version of a character using clay, pop it into the scanner, have it rapidly converted into a 3D computer model, and then continue to work on the design "virtually", on the computer workstation.

The clay then becomes the "front end" of the computer modelling system, the means by which the original model's shape is developed (perhaps crudely), before being tweaked by powerful software.

3D scanning makes a temporary Plasticine model permanent (inside the computer), and the ability to scan the model at multiple stages provides a form of "undo" function, letting one revert to an earlier version if subsequent poking and squishing then makes the model worse.

Advantages:

- Spontaneity – no matter how good a 3D sculpting computer interface might be, it can't be expected to be able to mimic the spontaneity of adding a twist to the corner of a model's mouth with the edge of your thumbnail.

- Tactility – Sculpting shapes on-screen has certain advantages (thanks to powerful tools that let one flatten or thin or smooth regions near the cursor), but they don't give the same skin feedback that you get by sculpting by hand. It risks becoming more of an analytic, intellectual exercise.

- Cost – Some physical 3D interfaces do exist that allow users to "sculpt" in empty space with their hands by moving an armature, and some of these systems do include armature "force feedback", so that the armature moves almost effortlessly through a region that is outside the computer model, but applies resistance when one digs the 3D cursor into the virtual surface. However, these systems are rather expensive (compared to Plasticine!) and don't normally allow you to use both hands.

While computer modelling can be excellent for constructing ultra-realistic figures, using libraries of anatomically correct skeletons, and systems for recreating natural variations in bodyshape and facial proportions, Clay is still great for the character development of more cartoonish 3D figures, and for trying out ideas for ficticious monsters, animals and aliens.

Doing character development in clay also lets a team compartmentalise the job of creating a cartoonish 3D character: an artist might be able to rapidly develop draft ideas in clay but not have professional-level 3D computer animation skills, while a computer artist might have skills to manipulate and improve the model, but might find the computer environment less inspiring and spontaneous. The danger of computer environments is that using the same tools over and over again can lead to similar designs and styles, which can become cliches: The clay artist has more obvious scope for randomness and inspiration: they can say: what happens if I pop into my bathroom and grab a toothbrush and use the handle as an sculpting tool? What happens if I use the "brush" end to stipple the surface to produce chin stubble? What happens if I use the ridged cap of the toothpaste tube as a roller for creating textured surfaces?

A photogrammetry test: Not a good idea

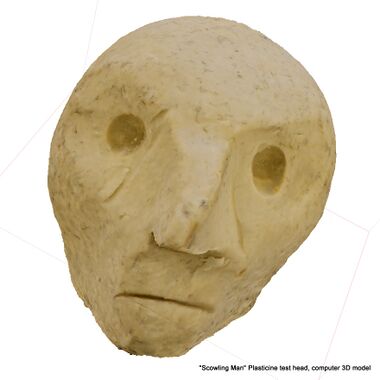

The Scowling Man: final computer model (cropped screenshot). Note the helpful embedded dust-fibres. Although this view looks not half bad as a recreation of the head, it's misleading, as a lot of the visual cues as to the shape are being provided by the shading of the photographic overlay: the "cut" mouth is obvious in this view as a dark line, but isn't satisfactorily expressed in the underlying 3D mesh. [image info]

The method of choice for scanning small "soft" clay or Plasticine sculptures is laser-scanning: It's possible to buy small enclosed 3D printers around the size of a microwave oven for less than a thousand pounds, that have an inbuilt turntable and 3D laser scanner, which can scan the contours of a small object (colour normally not being necessary for a clay model).

While photogrammetry can be used at a pinch for a dried or oven-fired rough clay model, such as terracotta (due to the resulting patterns of pitting in the surface, which the software can use as reference points), attempting to use photogrammetry on a smooth clay or Plasticine model is pretty much a non-starter, due to the almost total lack of pointlike surface detail.

In the interests of science, we thought we'd try anyway: taking a small (2cm) ball of NewPlas, we rolled it around on a table to make it spherical, and allowed the surface to pick up tiny particles of fluff to give it surface detail. We then pulled a nose out of the ball, squished either side with a thumbnail to create the impression of eyesockets, jabbed the lower face with a thumbnail edge to make a downturned mouth, and poked the face it with the wrong end of a small paintbrush to make a couple of eyes.

We then took a stack of photos of the "Scowling Man" head, and fed them into a piece of photogrammetry software.

While the resulting model kinda worked with a photographic texture applied (so that the Scowling Man is now preserved for posterity), the back of the head wasn't modelled consistently enough and ended up with a lumpy surface, as the software tried to reconcile different and inconsistent interpretations of where the surface ought to be. We also didn't succeed on our first try, and had to have a second go, with smaller angular differences between photos. It was all a bit tedious, and when the photographic overlay was turned off, the accuracy and clarity of the bare surface shape turned out to be not that great (which would be a bit of a problem if the whole point of the exercise was to import the bare shape into animation software for further processing).

- Conclusion

- As expected, attempting to scan a single-colour Plasticine model using photogrammetry is a really, really bad idea! Unless you can find a way to speckle the surface non-destructively, e.g. by dusting it with talcum powder or carbon black, it's a non-starter. Creating the actual head (from the rolled ball) took less than a minute, but converting it into a 3D model took 1.5-2 hours, which isn't acceptable for workflow. If we hadn't deliberately rolled table-fluff into the original ball surface, it might not have worked at all.