Category:Queen of Scots

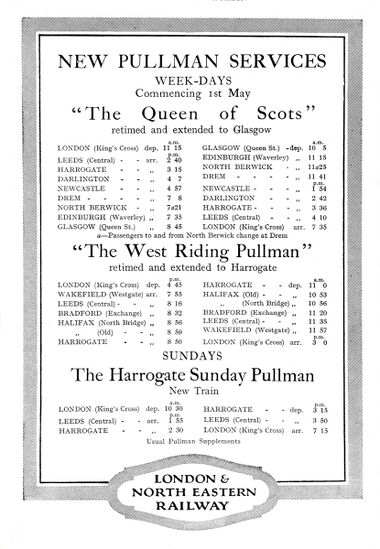

1928: New Pullman Services, Queen of Scots [image info]

1939: Hornby E120 Special Passenger Train Sets, including Queen of Scots [image info]

1928: new steel Pullman rolling-stock

NEW QUEEN OF SCOTS" PULLMAN TRAINS

The Pullman Company has had constructed at the works of the Metropolitan Carriage Wagon & Finance Co. Ltd. 29 Pullman cars, built entirely of steel, which is a notable departure from the usual practice of the Pullman Car Company. Care has been taken to maintain the known characteristics of Pullman cars, whilst in accordance with tradition, the comfort, convenience and safety of the passengers have been kept foremost in mind.

The wheels of the cars are built entirely of steel. The underframe is constructed as an integral part of the body, whilst the trussing, which is a feature of wooden cars has been dispensed with.

The principal dimensions of the cars are:–

- Length over vestibule connections

- 65 ft. 5 in.

- ... vestibules

- 63 ft. 10 in.

- ... corner pillars

- 57 ft. 1½ in.

- ... headstocks

- 62 ft. 4 in.

- Centres of bogies

- 43 ft. 4 in.

- Bogie wheelbase

- 10 ft.

- Height from rail to top of roof

- 12 ft. 5 in.

- Width over cornice

- 8 ft. 7 in.

- Wheels

- 3 ft. 6 in. diam. on tread.

- Axle journals

- 10 in. × 5 in. diam.

The floors of the cars, which are made up of dovetail corrugated galvanised-steel sheets are supported on subsidiary bearers formed of light-steel pressed channels which rest on the top of the under-frames. On these steel sheets is laid the "Induroleum" flooring, which in turn is covered in the third-class cars by a substantial patterned rubber mat, and in the first-class cars by linoleum and carpets. Either form a rigid sound-deadening and fireproof floor, differing only one from the other in degree of luxury.

The body sides are formed of a framework of vertical pressed U-shaped pillars, 1⁄8 in. thick, jointed laterally on the inside by means of a deep trussplate at the solebar, and on the outside by a rolled-steel channel at the waist, also a pressed-steel cantrail in which is incorporated an ample gutter to carry away the roof water to copper downpipes hidden in the hollow-pressed-steel corner pillars.

The side sheeting consists entirely of 1-in. mild-steel plate, the window opening being formed of pressings in the same material. Longitudinal mouldings have been eliminated, and the various plates are overlapped so that no ledges are formed to accumulate moisture and thereby cause corrosion. The standard Pullman ventilating window has been re-designed as a single unit, and consequent upon the use of metal for its frame it has been possible to add considerably to the height of glass forming the main window.

The roof carlines are formed of 11-in. steel pressings or angles as circumstances demand. The pressed carlines are so designed as to fit into the side pillars, forming thereby an annular construction. The carlines are joined laterally by means of 11-in. pressings on the inside and continuous rain angle gutters on the outside of the sheeting. The centre portion of the roof is covered by canvas to give more secure foothold than would be afforded by the bare metal sheets. The resultant structure is a roof of considerable stability combined with lightness.

Special attention has been-given in the design and construction of the vestibule ends of the cars to ensure that they will fully withstand the buffing shocks and strains brought about by the vestibule face-plate. The cars are insulated throughout against sound and variation of temperature. The vestibule drawgear is of the latest pattern, with automatic coupling, the centre draw and buff being taken by rubber springs of Spencer Moulton's manufacture, the whole being housed in a steel casting; side buffers are also provided which can be extended and brought into use as required. Special provision has been made to facilitate replacing the vestibule face-plate plungers and springs.

The vehicles are all dual braked, being fitted With 14-in. Westinghouse air cylinders and 24-in Westinghouse "Prestall" vacuum cylinders. The bogies are of the standard Pullman type with 10-ft. wheelbase, the easy riding qualities of which have always been recognised. Minor improvements have, however, been effected to facilitate maintenance. The Westinghouse steam-heating apparatus is of ample proportions; it is arranged to be controlled by the passengers as desired. The radiators are of 2-in. diam. piping, instead of 1 1⁄4 in., as has hitherto been employed in timber-built cars.

Ventilation is by means of "Imperiston" exhaust fans in each saloon, concealed behind ornamental grids in the ceiling, also torpedo ventilators, whilst the upper portion of the side windows can easily be opened by the passengers. Stone's system of electric lighting is fitted on all the cars. Satin-finished crystal shades, spaced around the dome of the ceilings, are used, torch brackets with similar shades being mounted on the cornice, whilst each table is furnished with a handsome lamp with silk shade in tones to suit the scheme of decoration. All cars are equipped with magnetic control, and a proportion of lighting in each vehicle can be switched on or off by a master control under the care of the guard.

The vestibule and corridor floors of the first-class cars are covered with black-and-white interlocking rubber tiling, and the third-class cars with black-and-white rubber matting. The vestibules, corridors and lavatories are panelled in mahogany. Each lavatory is provided with an oval light of obscured cathedral glass, and special attention has been given to ventilation. The fittings are of Twyford's manufacture finished in nickel, and hot water is supplied to the wash-basins by a Still's heater. The floors are covered with "Induroleum" in a design embodying colours of heather and green bordered by a black line.

Certain of of the cars are provided with kitchens and pantries, those for the third-class cars being somewhat larger than the first-class on account of the greater number of passengers to be served. Each kitchen is provided with a large Fletcher-Russell gas cooking range, whilst the third-class cars have in addition a Still's J. & S. gas-fired boiler for the supply of hot water. The water supply for the kitchens and pantries is carried in roof tanks in the kitchen. An "Imperiston" extractor fan, as well as a rotary ventilator and several torpedo ventilators provide ample ventilation. The pantries are fitted with shelving and cupboards to accommodate the various equipment. In the corners of the kitchen corridors are embodied ice chests and cupboards for the storage of silver. The brake vans are fitted with hand-brake gear, suitable heating apparatus, breakdown equipment, fire appliances and guard's electric food heater. Externally, the cars are of very handsome appearance, being finished in Pullman standard colours, viz., umber and cream, relieved with gold lines and scroll decoration.

Sixteen of the cars were placed in service on the L.N.E.R., as from Monday, July 9, replacing the "Queen of Scots" Pullman trains, which hitherto have been composed of timber-built vehicles. The two trains consist of eight coaches each. Five types of cars are employed. The seating of the third-class cars and the chairs of the first class are of much improved type, and should afford extreme comfort. The weight of each train, without locomotive, is approximately 320 tons.

The cars forming the two trains vary in interior design, upholstery and floor covering. The first- and third-class schemes have been carried out by Maple & Co., London, and Morison & Co., of Edinburgh, respectively. In all the cars, tables are provided with plate glass tops, and the brass furniture throughout is of tasteful design in ormolu gilt. The design and construction of the vehicles has been supervised throughout by Mr. W. S. Sedcole, Engineer of the Pullman Car Co. Ltd.

— , -, , Notable New Rolling-stock on British Railways, , The Railway Magazine, No.376, , October 1928

Media in category ‘Queen of Scots’

The following 2 files are in this category, out of 2 total.

- Hornby E120 Special Passenger Train (1939- catalogue).jpg 2,371 × 753; 502 KB

- New Pullman Services, LNER (TRM 1928-05).jpg 830 × 1,200; 263 KB